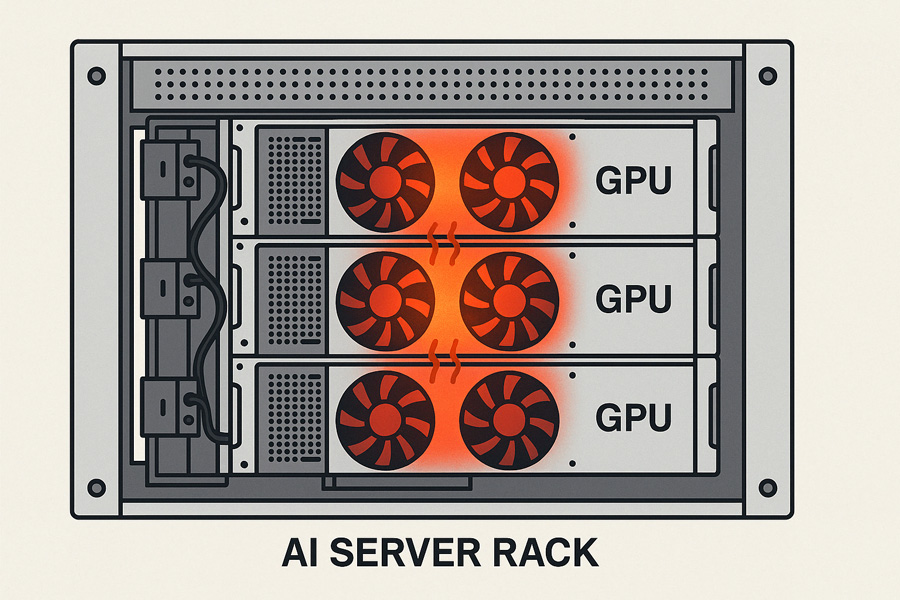

Artificial Intelligence (AI) is reshaping industries, but this computational revolution generates significant heat. As AI servers become increasingly powerful, you’ll find that traditional cooling methods struggle to keep pace. This article explores why advanced liquid cooling is critical for AI data centers and highlights the essential role high-reliability pumps play in ensuring the optimal performance and uptime you require.

The AI Heat Challenge: Where Traditional Cooling Falls Short

- Exponential Power & Heat: AI servers, driven by powerful GPUs and accelerators, consume vast amounts of electricity. This energy primarily converts into heat, creating thermal loads far exceeding those of traditional IT hardware. Managing this intense heat is a primary challenge you face in maintaining AI system stability and efficiency.

- Air Cooling’s Limitations: For decades, air cooling was the standard. However, as server rack power densities push beyond the 20kW threshold, air cooling becomes less efficient and more costly. It struggles to dissipate the concentrated heat from tightly packed AI components, risking performance throttling and hardware failure. Overcoming this limit is crucial for enabling denser, more powerful AI deployments.

The Liquid Cooling Imperative: Boosting Efficiency, Density, and Performance

Liquid cooling emerges as the necessary solution to handle demanding AI workloads. Here’s why it’s essential for you:

- Superior Heat Transfer: Liquids transfer heat far more effectively than air. This allows for significantly higher rack densities and improves energy efficiency, contributing to a lower Power Usage Effectiveness (PUE) or Total Usage Effectiveness (TUE) for your facility.

- Enabling Performance: By directly cooling processors and other hotspots, liquid cooling ensures optimal AI performance and prevents overheating. It enables the use of next-generation AI hardware that would be impossible to cool effectively with air alone.

| Feature | Traditional Air Cooling | Advanced Liquid Cooling |

|---|---|---|

| Cooling Efficiency | Moderate | Very High (up to 3000x vs. air) |

| Energy Efficiency | Lower | Higher |

| Component Temp. | Higher / Less Stable | Lower / More Stable |

| Infrastructure | Simpler, common | More complex, requires plumbing |

| Noise Level | High (Fans) | Lower (Pumps can be quiet) |

| Upfront Cost | Lower | Higher |

Air Cooling vs. Liquid Cooling for High-Density AI Racks

The Pump: Driving Your Liquid Cooling Ecosystem

In any liquid cooling loop—whether using Coolant Distribution Units (CDUs), direct-to-chip cold plates, or complex manifolds—the pump is the vital heart.

- Circulation Engine: It provides the necessary pressure and flow to circulate coolant continuously. This action transfers heat away from critical components like your GPUs and CPUs to where it can be safely dissipated. The pump’s performance directly dictates your cooling system’s effectiveness.

- Industry Adoption: The shift to liquid cooling is happening now. Major hyperscalers like Meta and Google, alongside research labs like the National Renewable Energy Laboratory (NREL), are pioneering large-scale liquid cooling deployments. Their work demonstrates the viability and necessity of this technology for managing the heat from massive AI and high-performance computing (HPC) infrastructure.

What Defines an Excellent Pump for Your AI Server Cooling Needs?

Pumps for AI liquid cooling aren’t standard components; they must meet stringent requirements you can depend on. Beyond basic flow and pressure, consider these critical characteristics:

- Exceptional Reliability: Ensures continuous operation and prevents costly downtime.

- Leak-Proof Design: Protects sensitive electronics.

- High Efficiency: Minimizes energy consumption (lower PUE/TUE).

- Quiet & Stable Operation: Reduces noise and vibration.

- Material Compatibility: Works reliably with various coolants.

- Intelligent Control: Integrates seamlessly with data center management systems.

Must-Have Pump Characteristics for Your Mission-Critical AI Environments

- Uncompromising Reliability (High MTBF): AI workloads often run 24/7. Cooling system failure can lead to catastrophic downtime. Therefore, you need pumps with extremely high Mean Time Between Failures (MTBF) for continuous operation. Long operational lifespans (e.g., 30,000 hours) are essential.

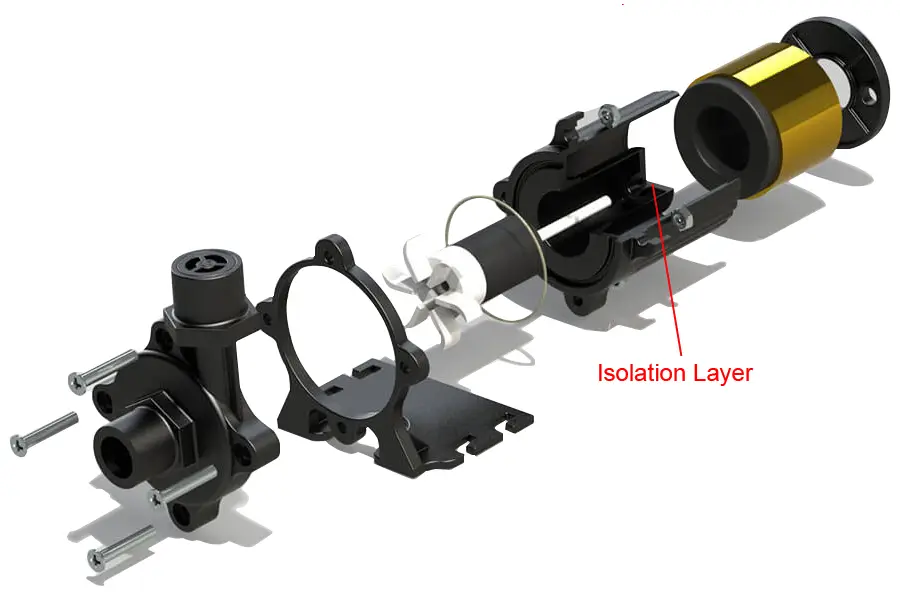

- Zero Tolerance for Leaks (Seal-less Design): Introducing liquids near electronics demands absolute leak prevention. Traditional pump seals are potential failure points. Seal-less designs, like magnetic drive pumps (where motor and pump chamber are magnetically coupled and physically separated), eliminate dynamic seals and offer you maximum protection.

- Optimized Energy Use (Efficiency & Control): Data center energy use is a major operating expense. Pumps significantly impact cooling energy consumption. High-efficiency motors, like Brushless DC (BLDC) motors, optimized performance curves, and Variable Speed Drives (VSDs) allow you to precisely match pump operation to cooling demand. This minimizes wasted energy and contributes to lower PUE/TUE.

- Stable and Silent Operation: While primarily industrial, data centers benefit from low noise (~35dB) and vibration for worker comfort and equipment stability. Look for pumps designed for quiet, low-vibration performance.

- Fluid Versatility (Material Compatibility): Liquid cooling uses various coolants (water, glycol mixtures, engineered fluids). Pump materials (casings, impellers, bearings) must be compatible to prevent corrosion and contamination. Ensure your supplier offers materials suitable for your specific coolant, possibly through customization.

- Smart Operations (Integration & Monitoring): Modern data centers rely on sophisticated control systems. Your pumps need integrated electronics for smart operation, including speed control (e.g., PWM, 0-5V) and status monitoring. Look for protective features (dry-run, locked-rotor, over/under-voltage) and custom programming options for seamless integration with your Building Management System (BMS) or CDU controller.

- Simplified Serviceability: Dense data center racks make maintenance challenging. Ideally, you want pumps designed for long operational lifespans with minimal or no required maintenance. Features that simplify diagnostics or replacement are also beneficial.

| Requirement | Why it’s Critical for AI Cooling | How BLDC PUMP Addresses It (Example) |

|---|---|---|

| High Reliability | Prevents costly downtime (24/7 operation) | ~30,000hr lifespan, robust design |

| Leak-Proof | Protects sensitive electronics from liquid damage | Magnetic Drive Seal-less technology |

| High Efficiency | Reduces data center PUE/TUE & operating costs | Efficient BLDC motor technology |

| Low Noise | Data center environment, equipment stability | Quiet operation (~35dB), smooth BLDC motor |

| Material Compat. | Ensures longevity with various coolants | Durable materials (Ceramic/Carbon), Customization |

| Smart Control | Integration with BMS, precise cooling adjustment | Integrated electronics, protections, custom programming |

| Low Maintenance | Reduces service needs in dense racks | Maintenance-free design |

Key Pump Requirements for AI Liquid Cooling

Dominant Pump Technologies in AI Liquid Cooling

- Centrifugal Pumps Lead: These are widely used due to their efficient, consistent flow and pressure.

- Seal-less Variants Preferred: For AI applications, seal-less magnetic drive or canned motor centrifugal pumps are strongly preferred. Their inherent leak-proof design and high reliability directly address your critical data center requirements.

- Market Landscape: The market includes large industrial manufacturers and specialized vendors focusing on electronics cooling or specific motor tech (like BLDC). Companies offering customization and direct B2B engagement with engineers like you play a key role in delivering tailored solutions.

Introducing BLDC PUMP and the Next-Generation DC95 Series

- Company Expertise (B2B Focus): Based in Shenzhen, China, BLDC PUMP specializes in standard and highly customized Brushless DC (BLDC) pump solutions via a B2B model. With a strong mechanical engineering team, we excel at collaborating with engineers and project managers like you to provide expert selection advice and develop tailored pump solutions.

- Performance Leap (DC95 Series): Recognizing your escalating cooling needs for AI servers, BLDC PUMP developed the DC95 series. This series offers a significant performance increase, capable of delivering up to 20,000 L/h @ 20m head or 6,000 L/h @ 45m head. This provides you the flexibility needed for various demanding liquid cooling loop designs. Explore our full range of solutions specifically engineered for AI server liquid cooling.

| Feature | Specification / Capability | Benefit for AI Cooling |

|---|---|---|

| Max Flow / Head Option 1 | 20,000 L/H @ 20M | High flow for less restrictive systems |

| Max Flow / Head Option 2 | 6,000 L/H @ 45M | High pressure for complex/restrictive loops |

| Drive Technology | Magnetic Drive Seal-less | Eliminates leak risk |

| Motor Type | Brushless DC (BLDC/EC Motor) | High efficiency, long life, controllability |

| Approx. Lifespan | 30,000 Hours | High reliability, reduced TCO |

| Noise Level | As low as ~35dB | Quiet operation |

| Maintenance | Maintenance-Free | Reduced service requirements |

| Control & Protection | Integrated Electronics, Custom Programming Opt. | Smart operation, system safety |

BLDC PUMP DC95 Series – Performance Highlights for AI Cooling

How BLDC PUMP Features Align with Your AI Cooling Needs

- Mitigating Leak Risks (Magnetic Drive): We utilize magnetic drive technology, providing a crucial seal-less architecture. This inherently leak-proof design directly addresses your need for zero fluid leakage in sensitive AI server environments.

- Achieving Quiet Stability (~35dB): Engineered for smooth operation, BLDC PUMP products run quietly (approx. 35dB) with minimal vibration. This contributes to a better working environment and equipment stability for you.

- Designing for Reliability (30,000hr Lifespan, Maintenance-Free): Built for longevity, our solutions boast an approximate 30,000-hour operational lifespan and are maintenance-free. This reduces service needs in dense racks, enhancing your system uptime and lowering total cost of ownership.

- Ensuring Compatibility (Robust Materials, Customization): We use durable materials like ceramic shafts and carbon-based bushings compatible with various coolants. We also offer customization to adapt pump materials for your specific coolant, ensuring chemical compatibility and system longevity.

- Enabling Smart Control (Integrated Electronics & Programming): Our pumps feature integrated controls (e.g., PWM speed adjustment) and essential protections. We collaborate with customers like you to develop custom control programs for seamless integration and tailored protection logic.

The BLDC PUMP Advantage for You: Efficiency, Reliability, Customization

- High Efficiency (BLDC Motors): The core of our products is the high-efficiency Brushless DC (BLDC) motor. This technology consumes less power than traditional AC motors, directly reducing your data center energy consumption and operating costs.

- Tailored Solutions (Expert Engineering Support): BLDC PUMP differentiates itself through customization and expert support. Our engineering team works directly with you to understand your specific requirements—performance, materials, control logic—delivering pump solutions precisely tailored to your unique AI liquid cooling project.

Conclusion

Future-Proofing Your AI Infrastructure with Advanced Pump Technology

As AI advances, thermal challenges intensify. High-performance, high-reliability liquid cooling is essential for the future of AI infrastructure. At the heart of these systems, pumps engineered for reliability, efficiency, leak-proof operation, and smart control are critical enablers for your required performance and uptime.

Partner with BLDC PUMP for Your Standard and Custom Cooling Needs

To ensure your AI infrastructure has robust and efficient cooling, partner with specialists. BLDC PUMP Co. offers standard high-performance pumps (like the DC95 series) and deep customization capabilities. Explore our solutions and leverage our engineering expertise to design the optimal liquid cooling loop for your mission-critical AI deployments. Visit https://www.bldcpump.com/ or contact our sales team to discuss your requirements.