Why Your Cold Plunge Pump Choice is More Critical Than You Think

A pump isn’t just an accessory; it’s the heart of your entire cold plunge ecosystem. Many fall for the common misconception that “any pump that moves water will work.” This seemingly simple oversight is the root cause of countless system failures. The core problem is that a mismatched pump creates a domino effect of poor performance, hidden costs, and constant frustration, turning a sanctuary for recovery into a source of stress. For more general guidance on selecting the right pump for various applications, refer to our comprehensive pump selection guide.

The Unseen Consequences of a Bad Decision

Nightmare #1: The TCO Trap – How a “Cheap” Pump Drains Your Wallet

The true cost of a pump extends far beyond its initial purchase price. The Total Cost of Ownership (TCO) reveals the hidden expenses that accumulate over time, primarily through energy consumption. There is a massive difference in energy consumption between a standard, inexpensive AC (Alternating Current) pump and a modern BLDC (Brushless DC) pump. Choosing a cheap AC pump is like buying a car with terrible fuel economy – you might save a little upfront, but you pay for that decision every single day on your electricity bill. A high-efficiency BLDC pump, by contrast, can reduce energy usage by up to 70%, translating into significant savings over the lifespan of your system.

Nightmare #2: The Constant Hum – When Your Sanctuary Becomes a Source of Noise

The cold plunge experience is meant to be meditative and restorative. This is completely undermined by a loud, vibrating pump. When evaluating pumps, subjective terms like “quiet” are meaningless marketing fluff. You must demand quantifiable data. Understanding the decibel (dB) rating is crucial. A typical AC pump can operate at 60-70 dB, the equivalent of a busy restaurant or a vacuum cleaner. In contrast, an acoustically engineered BLDC pump can operate below 35 dB, which is quieter than a library. This difference is not trivial; it’s the distinction between a peaceful retreat and a noisy appliance, especially for indoor or residential setups where noise pollution is a primary concern.

Nightmare #3: System Synergy Failure – Inefficient Cooling & Murky Water

Your cold plunge is a delicate ecosystem where every component must work in harmony. A pump that fails to achieve “system synergy” will cause cascading failures. The primary obstacle it must overcome is Head Loss—the total resistance from your chiller, filter, and the friction within your piping. If a pump isn’t powerful enough to overcome this resistance, the consequences are severe:

- Flow Rate Mismatch: Your water chiller has an optimal flow rate, measured in Gallons Per Minute (GPM), required for maximum efficiency. A pump that delivers a GPM below this threshold will cripple your chiller’s ability to cool the water effectively, forcing it to run longer and harder, which wastes energy and shortens its lifespan.

- Poor Filtration: Effective filtration depends on a consistent and adequate flow rate to push water through the filter media. Inadequate flow leads to stagnant zones, cloudy water, and a buildup of contaminants, creating an unhygienic and unsafe environment.

- Sanitation Breakdown: If you use an Ozone or UV sanitation system, your pump’s performance is critical. A stable, continuous flow is necessary to ensure proper ozone mixing and dissolution into the water. For UV sanitizers, the flow rate determines the “contact time”—how long pathogens are exposed to the sterilizing UV light. Too fast, and the water isn’t sanitized; too slow, and your circulation suffers.

The Solution: A Step-by-Step Guide to Selecting the Perfect Pump

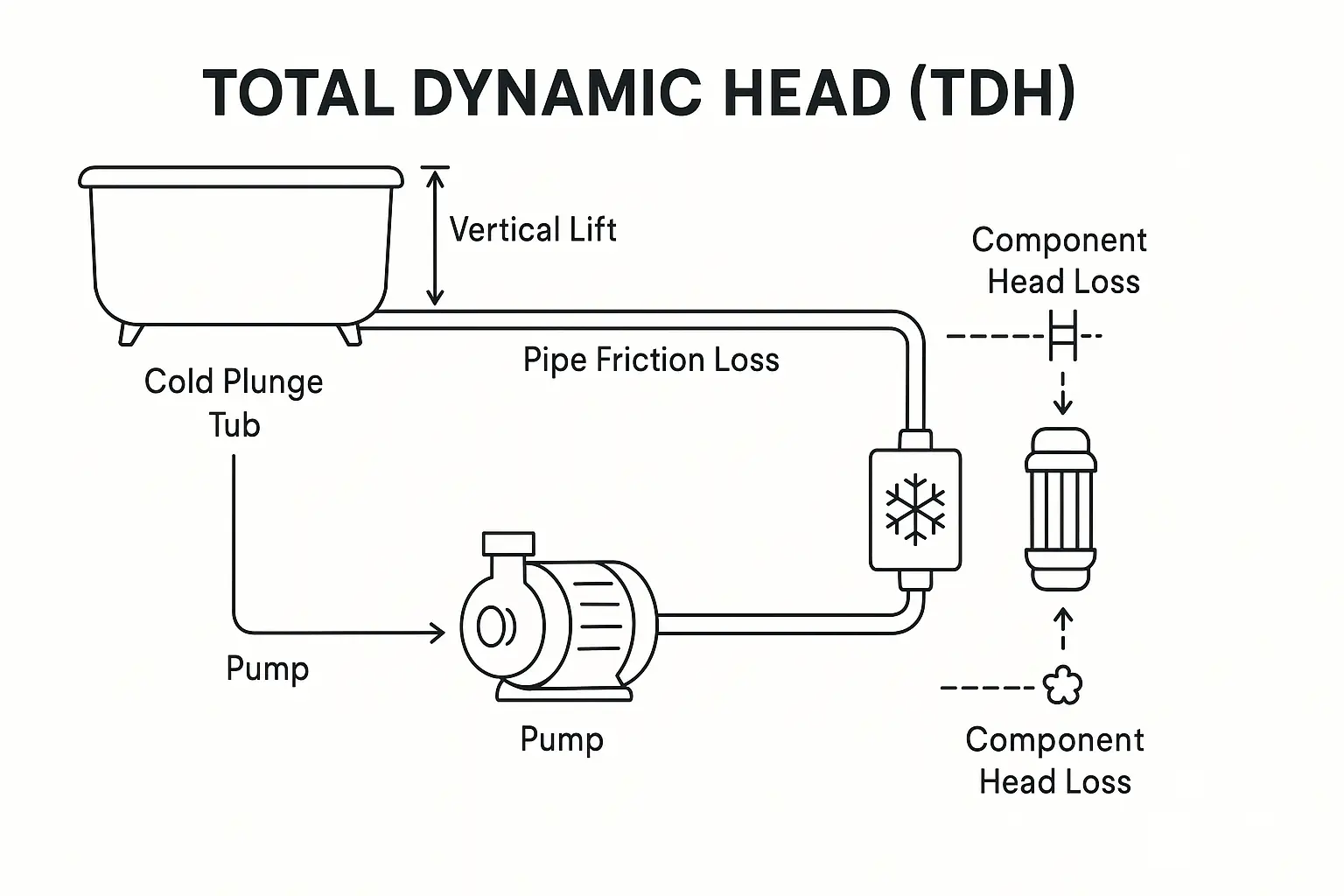

Step 1: Calculate Your Core Metrics – GPM & Total Dynamic Head

First, determine the required flow rate for your system. A good rule of thumb is to circulate the entire volume of your tub 4 to 6 times per hour. To calculate your target GPM: (Tub Volume in Gallons x 5) / 60 minutes. For a 100-gallon tub, this would be (100 x 5) / 60 = ~8.3 GPM.

Next, estimate your system’s Total Dynamic Head (TDH) or head loss. For most DIY and pre-built cold plunge setups, a simplified estimation works:

- Start with the vertical height from the pump to the highest point water will reach.

- Add 1 foot of head for every 10 feet of horizontal pipe.

- Add significant head for each component: a chiller can add 5-10 feet, and a dense filter can add another 4-8 feet. Always check your chiller and filter manuals for their specific head loss ratings and select a pump that exceeds the calculated total.

Step 2: Prioritize Technology for Long-Term Value (BLDC vs. AC)

The single most important technological choice you can make is selecting a BLDC (Brushless DC) motor over a traditional AC motor. BLDC technology is the superior choice for three critical reasons:

- Benefit 1: Drastically Lower Energy Consumption: BLDC motors are inherently more efficient, consuming significantly less power to perform the same amount of work. This leads to direct and substantial savings on your electricity bill.

- Benefit 2: Significantly Quieter Operation: The brushless design eliminates the noise-generating friction and vibration common in AC pumps, resulting in near-silent operation.

- Benefit 3: Longer Lifespan and Reliability: With fewer wearing parts and less heat generation, BLDC pumps are built for continuous operation and have a much longer service life than their AC counterparts.

Step 3: Ensure Total System Compatibility

Use this checklist to ensure your chosen pump integrates flawlessly with your entire system:

- Chiller Flow Rate: Does the pump’s GPM at your estimated TDH meet or comfortably exceed the minimum flow rate required by your chiller? Always prioritize the chiller’s requirement.

- Filter Compatibility: Is the flow rate appropriate for your filter type to ensure effective particle capture without channeling or bypassing?

- Plumbing Size: Do the pump’s inlet and outlet ports match your system’s plumbing diameter (e.g., 3/4″, 1″)? Using adapters can create additional points of failure and flow restriction.

- Sanitation Synergy:

- Ozone & UV Sanitizers: A pump’s GPM directly impacts the effectiveness of sanitizers. For UV systems, the flow must be slow enough to achieve the necessary “contact time” for sterilization. For ozone, the stable, continuous operation of a BLDC pump is critical for ensuring the ozone is properly mixed and dissolved into the water for maximum sanitation. A pump that cycles on and off or has an inconsistent flow will render these systems ineffective.

The Ultimate Pump Selection Checklist: A Summary

When evaluating any pump, verify these key points:

- Performance: Does it provide the required GPM after accounting for my system’s Total Dynamic Head?

- Technology: Is it a high-efficiency, quiet, and durable BLDC pump?

- Compatibility: Does it meet the specific flow requirements of my chiller, filter, and sanitation system?

- Data: Does the manufacturer provide clear, quantifiable data for power consumption (Watts) and noise level (dB)?

Spec & Cost Comparison Table: A Head-to-Head Analysis

This table illustrates the dramatic difference in long-term value between a generic AC pump and a purpose-built BLDC pump.

| Metric | Standard AC Pump | Our BLDC Pump |

|---|---|---|

| Initial Price | Lower | Higher |

| Energy Efficiency | Standard Consumption | High-Efficiency (Up to 70% Less Power Usage) |

| Long-Term Operating Cost | High (Approx. 2.5x – 3x higher electricity cost) | Significantly Lower (Pays for itself in energy savings) |

| Noise Level (dB) | 65 dB (Normal Conversation) | <35 dB (Quiet Library) |

| Core Technology | AC (Alternating Current) | BLDC (Brushless DC) |

| Warranty | 1 Year (Typical) | 2+ Years |

Comparative Analysis: Standard AC Pump vs. High-Performance BLDC Pump for Cold Plunge Tubs

Of course. Here is the English version of that conclusion, ready to be added to your article.

The Real-World Savings: A Quick Calculation

To give you a more intuitive sense of this efficiency difference, let’s take a 200W BLDC pump as an example. Based on the 2.5x multiplier, a comparable AC pump would consume around 500W to perform the same work.

Assuming the pump runs for 12 hours per day at an average U.S. electricity rate of $0.17 per kWh, the annual costs break down as follows:

- Annual Cost for an AC Pump:

(500W × 12 hours/day × 365 days) / 1000 * $0.17/kWh = $372.30 - Annual Cost for our BLDC Pump:

(200W × 12 hours/day × 365 days) / 1000 * $0.17/kWh = $148.92

This means that choosing a BLDC pump saves you approximately $223 per year in electricity costs alone. These savings can often cover the initial price difference between a BLDC and an AC pump in just 1-2 years, making it a true long-term value investment.

Practical Guidance: Installation & Support

Quick Installation Tips

- Priming the Pump: Before the first start, ensure the pump housing is filled with water to prevent it from running dry.

- Positioning: Place the pump on a level surface, ideally on a vibration-dampening pad, as low as possible in the system to assist with priming.

- Plumbing: Use smooth, direct plumbing routes where possible. Avoid sharp 90-degree bends, as they significantly increase head loss.

Troubleshooting & Maintenance

Common issues like low flow or noise are often related to air leaks in the suction line or a clogged filter. Regularly check connections and clean your filter basket.

Note: For detailed instructions, please refer to our full Product Usage and Support documentation.

Applying the Framework: Why Our DC85E Series is the Professional’s Choice

Why It’s the Professional’s Choice

Our DC85E series of BLDC pumps was engineered from the ground up to solve the core problems of noise, inefficiency, and system incompatibility.

- Ultra-Quiet Operation: With industry-leading low decibel ratings (<35dB), our pumps ensure your cold plunge remains a peaceful sanctuary.

- Unmatched Energy Efficiency: Save up to 70% on electricity costs compared to standard AC pumps, thanks to advanced BLDC motor technology. The higher initial investment pays for itself in energy savings.

- Optimized for System Synergy: The DC85E series is designed with versatile and adjustable flow rates to perfectly match the requirements of leading chillers, filters, and sanitation systems.

- Built for Durability: Engineered with corrosion-resistant materials, our pumps are built to withstand the unique demands of low-temperature water and common water treatment chemicals, ensuring long-term reliability.

Ideal Application Scenarios

- For Your 100-150 Gallon Stock Tank DIY Project: The DC85E provides the perfect balance of flow and pressure to efficiently run a compact chiller and filter, all while operating silently in your garage or backyard.

- Commercial Use for Gyms & Wellness Centers: For facilities where reliability and low operating costs are paramount, the continuous-duty rating and extreme energy efficiency of the DC85E series deliver professional-grade performance and a rapid return on investment.

- Silence is Golden: The Ultra-Quiet Solution for Apartments & Indoor Tubs: When noise is not an option, the sub-35dB performance of the DC85E is the only choice for indoor cold plunge setups, ensuring you and your neighbors are never disturbed.

FAQ: Your Cold Plunge Pump Questions Answered

Q1: Do I absolutely need a pump for my cold plunge?

Yes. Without a pump, you have no circulation. This means no filtration, no effective chilling, and stagnant water that quickly becomes a breeding ground for bacteria. A pump is non-negotiable for a safe and effective cold plunge.

Q2: What’s the real difference between a pump, a chiller, and a filter?

Think of them as the heart, lungs, and kidneys of your system. The Pump (heart) circulates the water. The Chiller (lungs) cools the water as it passes through. The Filter (kidneys) removes physical debris and contaminants from the water. All three must work together.

Q3: To maintain water quality and temperature, how many hours should my pump run daily, and what’s the advantage of a BLDC pump here?

For optimal water quality and temperature stability, it’s best to run the pump continuously (24/7) at a low flow setting or for at least 12 hours per day. This is where a BLDC pump’s advantage becomes undeniable. Its extreme energy efficiency makes 24/7 operation affordable, while a standard AC pump would lead to prohibitively high electricity bills.

Q4: What is a BLDC pump and why is it worth the investment?

A BLDC (Brushless DC) pump uses magnets and advanced electronics to create rotation, eliminating the physical “brushes” found in older motor designs. This results in dramatically less friction, heat, noise, and energy use. It’s worth the investment because it saves you significant money on electricity over its longer lifespan and provides a superior, silent user experience.

Q5: How can I simply estimate my system’s head loss?

A simple way is to add up the resistance from each component. Check the manual for your chiller and filter—they will often list their head loss (e.g., “adds 8 feet of head”). Add that to the vertical height the water must be pumped. For every 10 feet of pipe, add 1 foot of head. Summing these numbers gives you a solid estimate to use when looking at a pump’s performance chart.

Take the Next Step

Ready to build a silent, efficient, and perfectly chilled cold plunge system? Explore our range of DC85E series BLDC pumps or contact our system specialists for a personalized consultation. We also offer custom services to design an ecosystem that performs flawlessly from day one.